From SHEIN to TEMU: Can Global Logistics Sustain the Low-Price Wave?

A survival playbook for EU & North American buyers who consolidate China shipments

Executive summary (you can keep this as a collapsible block)

Over the past three years, a surge of low-value, direct-to-consumer parcels from platforms like SHEIN, TEMU, AliExpress, Amazon, and eBay has reshaped global air freight. Volumes exploded; profits did not. Postal operators, airlines, and 3PLs find themselves in a thin-margin grind, while policy shifts—most notably the end of de minimis for the U.S.—force a structural reset.

For European and North American importers who consolidate China shipments, the path forward is clear: scale up consolidation, regionalise inventories via overseas warehouses, harden compliance (HS codes, data quality, IOR/EOR), and optimise packaging & returns. This article explains why, how, and in what sequence.

1) The low-price boom that overloaded global logistics

“Shop like a billionaire” wasn’t just a catchy line—it triggered a behavioural shift. Shoppers embraced ultra-cheap electronics, fast-fashion and home goods; merchants in China shipped single-item DTC parcels at unprecedented scale; airlines and postal networks became the circulatory system of this new retail organism.

Three forces created the perfect storm:

- Platform incentives – Discounts, coupons, free shipping, paid returns, and prime-like delivery promises pushed checkout conversion but shifted costs downstream.

- Operational shortcuts – Splitting orders into many small parcels reduced per-item duties under legacy regimes and exploited small-packet postal lanes.

- Demand elasticity at ultra-low prices – A USD 6 phone case with “free” shipping converts instantly; a USD 12 dress drops into carts by the millions.

The result: air freight share of global cargo climbed sharply, particularly Asia→EU and Asia→US. Yet the cash that kept planes flying didn’t scale in step with costs (aviation fuel, labour, handling, security, data filings). This is the paradox: volume up, margins flat or negative.

2) Why profits lag despite record parcel volumes

Think of each small parcel as a mini-project with fixed steps—pickup, sortation, export clearance, airlift, import entry, last-mile. Low ticket values cannot absorb rising costs at each node. Add returns, address corrections, re-delivery attempts, duty advances, and payment gateway fees, and the unit economics quickly flip.

Four structural drains on margin:

- Compliance drag: Modern customs requires accurate HS codes, product attributes, and digital pre-advice (ITMATT/AEI). Every missing field = a delay or manual touch = cost.

- Network congestion: The more you route through postal small-packet lanes, the more you compete for limited processing capacity at peak.

- Reverse logistics: Generous free returns policies explode costs that are invisible at checkout but very visible in P&L.

- Price opacity: Predatory pricing (or deep subsidisation) can scale GMV while silently burning cash in logistics.

For airlines and postal operators, the picture echoes passenger aviation’s low-fare trap: price competition outpaces productivity gains, so the industry runs faster to stand still.

3) Policy shock: why the U.S. de minimis end matters to everyone

Even for EU-based buyers, the U.S. policy pivot is a global signal. When a top-3 import market ends low-value exemptions and pushes full declarations onto carriers and airlines, everyone upstream must upgrade data, systems, and workflows.

What this means for EU/NA importers who consolidate China goods:

- Fragmented DTC flows get penalised. Each extra parcel is another declaration, fee, touchpoint, risk of inspection/return.

- Bulk is better. A single Master Air Waybill (MAWB) or FCL/LCL with one high-quality dataset clears faster than 100 sketchy small packets.

- Data becomes a moat. Clean HS codes, brand/model, materials, intended use, and compliant values reduce queries and holds.

Takeaway: The logistics winners won’t be the cheapest labels this week, but the shippers with the cleanest data + scalable consolidation.

4) What changes for EU & North American buyers using consolidation?

Good news: if you already consolidate China shipments, you’re ahead of the curve. Consolidation neutralises many pain points:

- Duty efficiency – Aggregate values under one entry; leverage correct valuation & origin proofs; reduce per-parcel minimum fees.

- Predictability – A planned ocean/rail/air + bonded warehouse cadence beats ad-hoc micro-parcels.

- Cost control – Fewer touches, negotiated linehaul, stable last-mile partners.

- Customer experience – Faster domestic delivery once inventory lands in EU (e.g., Budapest/Rotterdam/Frankfurt) or NA (e.g., LA/Chicago/Toronto) hubs.

Where consolidators still stumble: missing attributes in product master data; poor cartonisation; oversized packaging; lack of returns plan; and unclear Importer/Exporter of Record (IOR/EOR) responsibilities. Fix these and consolidation becomes your enduring advantage.

5) The new cost stack—explained with a realistic calculator

When low-value DTC lanes lose their privilege, your landed cost changes structure. Here’s a practical framework for decision-making:

Landed Cost =

Product ex-works + Domestic lift + Export handling + Main carriage (air/sea/rail) + Import duty & VAT/GST + Brokerage/entry + Bonded handling + De-consolidation + Domestic last-mile + Returns provision

Compare three strategies for the same 100-item order (unit value USD 15):

- Micro-parcel DTC

- Pros: instant market access, no inventory holding.

- Cons: duty on every parcel; per-parcel fees; unpredictable lead time; high returns cost; data errors magnified 100×.

- Typical landed cost index: 100–135 (volatile).

- Air consolidation + domestic courier

- Pros: fast; one entry; stable linehaul; predictable delivery.

- Cons: still higher airlift cost; requires better data discipline.

- Landed cost index: 85–105 (manageable at scale).

- Sea LCL/FCL consolidation + overseas warehouse

- Pros: lowest per-unit freight; one entry per lot; fastest domestic delivery; superior returns/re-work control.

- Cons: working capital & inventory planning; requires demand forecasting.

- Landed cost index: 70–90 (most resilient beyond policy shocks).

Rule of thumb: if your parcel count per SKU per week > 50–100 to the same region, your inflection point to sea/rail consolidation + warehouse is already here.

6) Air vs sea vs rail: when to choose which

- Air (consol) – Use for product launches, urgency, high seasonality, or high ASP/lightweight items (electronics accessories, jewellery).

- Rail (China–EU) – A sweet spot for Central/Eastern Europe: faster than ocean, cheaper than air, robust for cartons/pallets.

- Ocean (LCL/FCL) – Your baseline for staples & replenishment. Pair with weekly cut-offs and rolling forecasts to stabilise cashflow.

Pro tip: Split your catalog into A/B/C velocity buckets. Fly A-items initially, replenish by rail/sea. Keep safety stock at EU/NA hub to avoid surge pricing.

7) The compliance edge: data is the new fuel

Customs authorities increasingly reject “fuzzy” declarations. Your Product Information File (PIF) should include:

- HS code (6/8/10-digit where applicable), materials composition, brand/model, intended use, key dimensions/weight

- Regulatory flags (CE/UKCA/FCC/RoHS/REACH/Toy safety), certificates & test reports

- Country of origin; <origin rules>; valuation basis; incoterms

- Battery/magnet/chemical/food/cosmetic flags with UN numbers if relevant

Workflow you can copy:

- Build a central SKU master with the fields above.

- Validate HS codes with dual checks (internal classifier + broker).

- Lock attribute governance (no last-minute changes after booking).

- Send pre-advice (ITMATT/AEI) before freight acceptance.

- Audit 2–5 % of entries monthly; fix root causes.

IOR/EOR clarity: Decide who is the Importer of Record in EU/NA and who files the export in CN. Get power-of-attorney and EORI/BN/US EIN in place before your volumes spike.

8) Packaging, cartonisation, DIM weight: how to stop shipping air

Low-value items are hypersensitive to dimensional weight. Optimise:

- Right-size cartons; use fit-for-purpose mailers

- Bundle SKUs to hit DIM sweet spots and save pick fees

- Kitting at origin to cut handling at destination

- Use a cartonisation engine (even a simple rule-based one) to simulate pack plans before PO release

A 10–15 % reduction in average package volume often yields 5–8 % total landed cost savings and a measurable CO₂ improvement you can report.

9) Returns & after-sales: the quiet margin killer

Free returns are not free. For cross-border flows:

- Offer keep-it or partial refund logic below a threshold.

- Use local consolidation points for returns; re-work, re-label, or liquidate domestically.

- For apparel, fit guidance and photo-based size tools can cut returns by 10–20 %.

- Track reasons (damage, wrong item, size, quality) to drive upstream vendor QA.

A returns rate cut from 18 % → 12 % can recover 3–5 margin points, more than any spot freight discount.

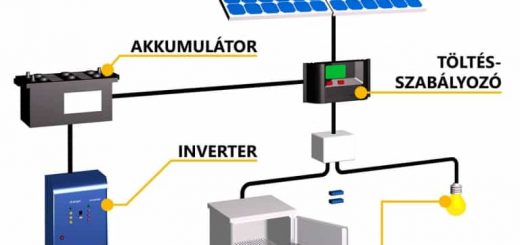

10) Overseas warehouse strategy for EU & North America

EU hubs to consider:

- Central Europe (Budapest/Prague/Warsaw) – excellent for east-west balancing, rail/ocean connectivity, competitive labour.

- Western EU (Rotterdam/Antwerp/Frankfurt) – prime gateways, fast customs, dense parcel networks.

North America hubs to consider:

- U.S. West (Los Angeles/Long Beach + Inland Empire) – Asia gateways, strong parcel & LTL coverage.

- U.S. Midwest (Chicago) – time-zone & linehaul sweet spot.

- Canada (Toronto/Mississauga) – leverage CUSMA, diversify duty exposure, serve Northeast U.S. regionally.

Operating model:

- Inbound by FCL/LCL/air consol → bonded in-bound handling → ASN-based putaway → B2C/B2B pick-pack-ship → returns re-work.

- Add value-added services (kitting, relabelling for EU languages, packaging upgrades, battery marks).

11) Payments, taxes, and Incoterms (DDP vs DAP)

- DDP (Delivered Duty Paid) smooths checkout but requires accurate pre-calc of duties/VAT and competent brokers; best for repeatable SKUs.

- DAP/DDU (Delivered At Place/Unpaid) shifts duty payment to recipient—expect abandonment if surprises hit.

- In the EU, maintain clarity on IOSS for low-value consignments to avoid double taxation or holds.

- In NA, ensure your tax registrations (U.S. state nexus rules / Canadian BN & GST/HST) are scoped with an accountant.

12) 30-60-90 day action plan (copy/paste to your project tracker)

Day 0–30 (Stabilise)

- SKU master data cleanup; assign HS, materials, compliance docs

- Pick one consolidator & one customs broker per region

- Pilot air consol for top 20 SKUs; measure landed cost & cycle time

- Start packaging right-sizing; approve 2 alt mailers

Day 31–60 (Scale)

- Book first LCL/FCL to EU hub; define safety stock policy

- Contract domestic parcel + returns consolidation point

- Implement RMA rules (keep-it thresholds; re-work SOPs)

- Turn on basic cartonisation rules in OMS/WMS

Day 61–90 (Optimise)

- Add rail leg for Central/Eastern EU lanes

- Forecasting cadence (weekly S&OP; 12-week rolling)

- Broker SLA: query turnaround < 24 h; entry error rate < 1 %

- Quarterly “landed cost” review; target −8–12 % vs pre-consol baseline

13) Case snapshots (EU & NA)

Case A – EU fashion accessories brand (DE/FR/ES)

- Problem: 40–55 % of orders shipped as CN micro-parcels; 14–18 days lead-time; 19 % returns.

- Fix: Sea LCL to Rotterdam + DE hub, then EU parcel; size tool + keep-it ≤ €9.

- Result (90 days): landed cost −17 %, delivery 2–4 days, returns 19 → 13 %.

Case B – NA home gadgets (U.S./Canada)

- Problem: Air postal lanes unstable; duty shocks; oversize packaging.

- Fix: Air consol for launches, FCL to LA, crossdock to U.S./CA; cartonisation engine deployed.

- Result: On-time +12 pts, DIM weight −11 %, margin +4.2 pts.

14) Risk radar for 2025–2026

- Policy churn: More markets may tighten low-value regimes; watch product-specific measures (textiles/footwear/electronics).

- Capacity swings: Peak season airlift volatility; book blocks early; diversify to rail/sea.

- Data enforcement: Penalties & holds for vague descriptions (“gift”, “electronics”).

- ESG scrutiny: Packaging waste, labour transparency, and product safety audits move from “nice to have” to table stakes.

15) KPIs that truly matter (and their target ranges)

- Entry error rate < 1 % (broker + internal checks)

- On-time final delivery ≥ 95 % (D+X by lane)

- Avg DIM / parcel −10 % vs baseline (packaging program)

- Returns rate −20–35 % vs baseline for top 30 SKUs

- Landed-cost index −8–15 % by month 3 of consolidation

- Inventory turns ≥ 8–10 (fast category) at overseas hubs

16) Tooling stack you can assemble this quarter

- Classification & duty calc: broker portal + a rules-based classifier (export HS → import HS mapping)

- Cartonisation: rule engine inside WMS/OMS; simulate pack plans pre-PO

- Forecasting: rolling 12-week S&OP + weekly exception review

- Label/Docs: auto-generate CN export + EU/NA import packs; enforce attribute locks

- Returns: RMA portal with reason codes; domestic consolidation points per region

17) FAQs for EU/NA buyers who consolidate China shipments

Q1: Is air consolidation still viable after policy tightening?

Yes. For high-velocity SKUs and launches, air consol remains a critical lever—provided your data is clean and you pre-advise entries.

Q2: We are small—do we really need an overseas warehouse?

Not day one. Start with shared (multi-tenant) facilities where you only pay for space/activity. Shift to dedicated space as volumes justify.

Q3: What about IOSS in the EU?

If you keep shipping low-value B2C parcels, IOSS prevents double VAT but doesn’t fix duty exposure or handling bottlenecks. Consolidation + warehousing is the more scalable fix.

Q4: Should we choose DDP or DAP?

For conversion and CX, DDP wins—but only if you can estimate duties correctly and file clean data. Otherwise use DAP with clear pre-purchase duty estimates.

Q5: How do we cut returns quickly?

Fit tools (for apparel), better product imagery, keep-it threshold for low-value items, and local re-work to avoid cross-border bounce-backs.

18) Actionable checklist (print-ready)

- Build SKU master (HS, materials, certificates, brand/model)

- Select one consolidator + one broker per region

- Approve right-sized packaging & two alternate mailers

- Go live with air consol for top 20 SKUs (pilot)

- Book first LCL/FCL to EU or NA hub; define safety stock

- Turn on cartonisation rules; measure DIM reduction

- Stand up returns consolidation point; set keep-it rules

- Review landed-cost index monthly; drive −10 % within 90 days

Conclusion: The era of cheap & frictionless is over—resilience wins

The DTC micro-parcel boom proved what price can do to demand. It also proved what cost and compliance can do to margins. As postal lanes tighten and duties bite, a new operating model becomes dominant: consolidate at origin, clear with clean data, store closer to customers, and deliver domestically.

For EU and North American buyers who consolidate China shipments, this transition is not a threat but an opportunity to lock in predictable lead times, lower landed costs, and better customer experience—the three ingredients of durable growth.

Need a lane-by-lane quote or a 48-hour feasibility plan?

Get a consolidation & overseas-warehouse plan tailored to your SKUs and destinations.

➡️ Request a plan: /contact/ | Email: ops@yourdomain | WhatsApp/WeChat: +86-xxx-xxxx-xxxx